Services

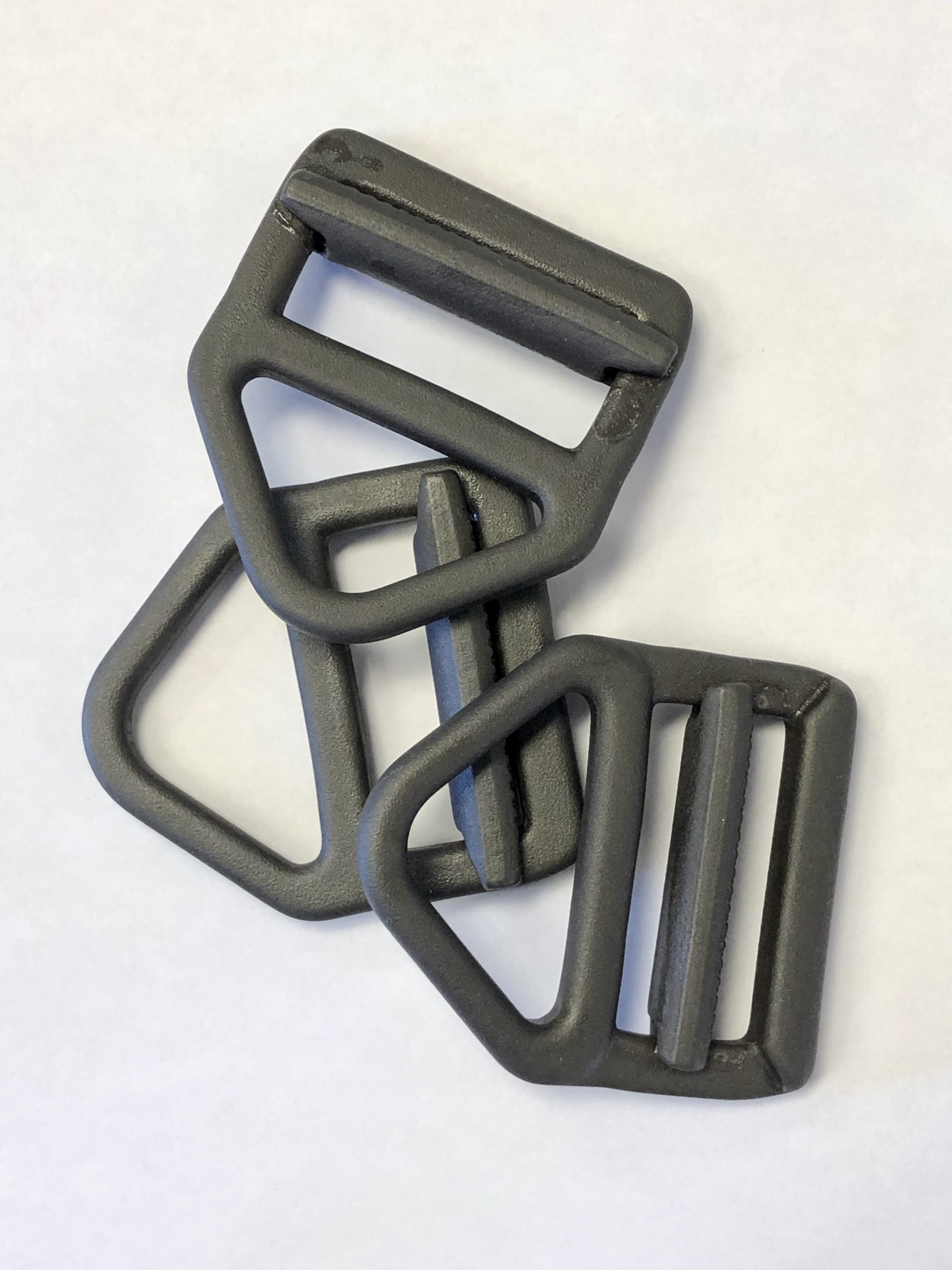

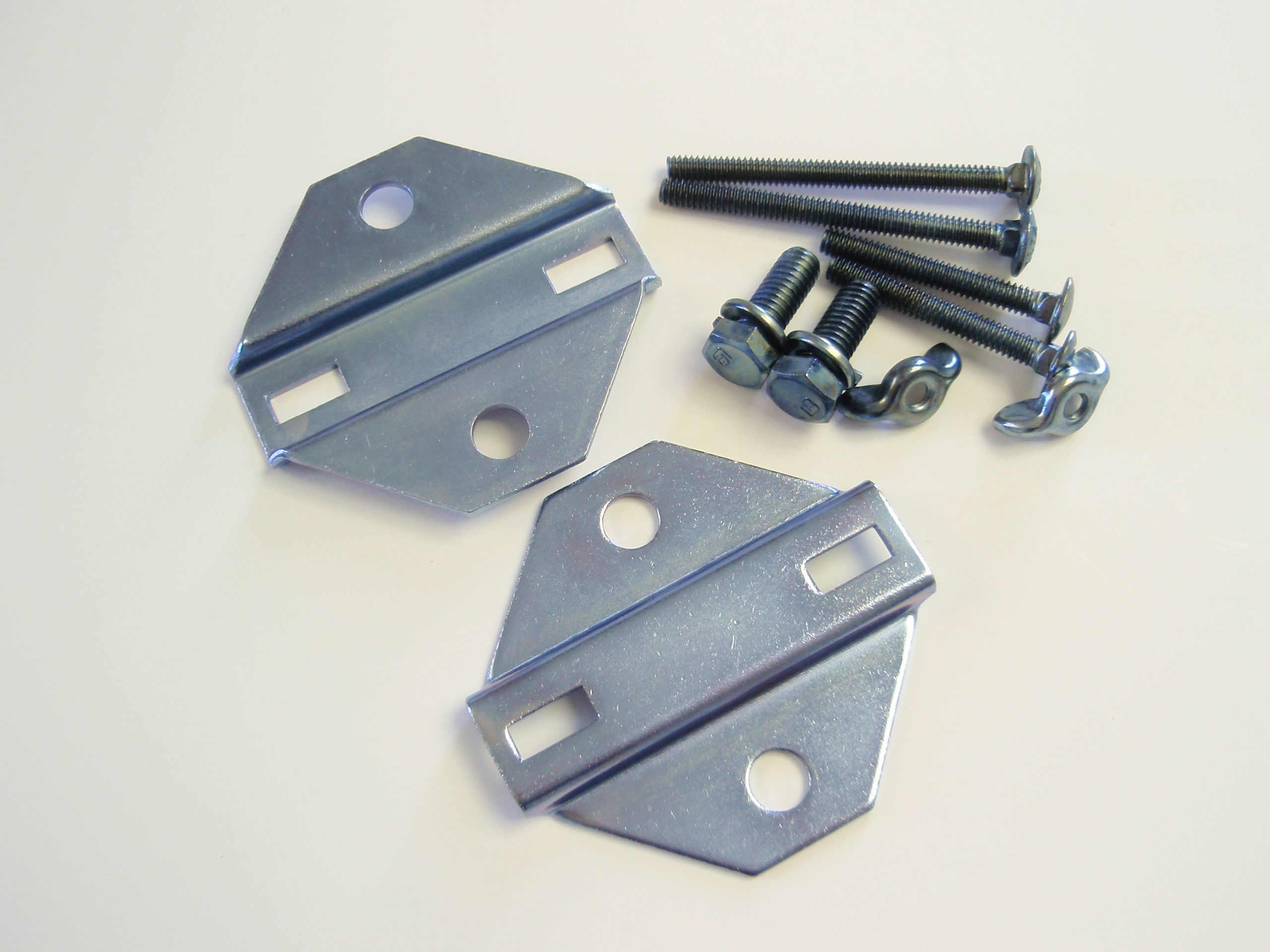

Zinc plating provides a sacrificial, corrosion resistant coating on iron and steel. The modest cost, attractive appearance and sacrificial nature of zinc make it a popular coating for use on fasteners, wire goods, machined and formed metal parts. Our ‘Pro-T’ clear passivate for zinc plating meets current EU environmental requirements while yielding impressive corrosion protection.

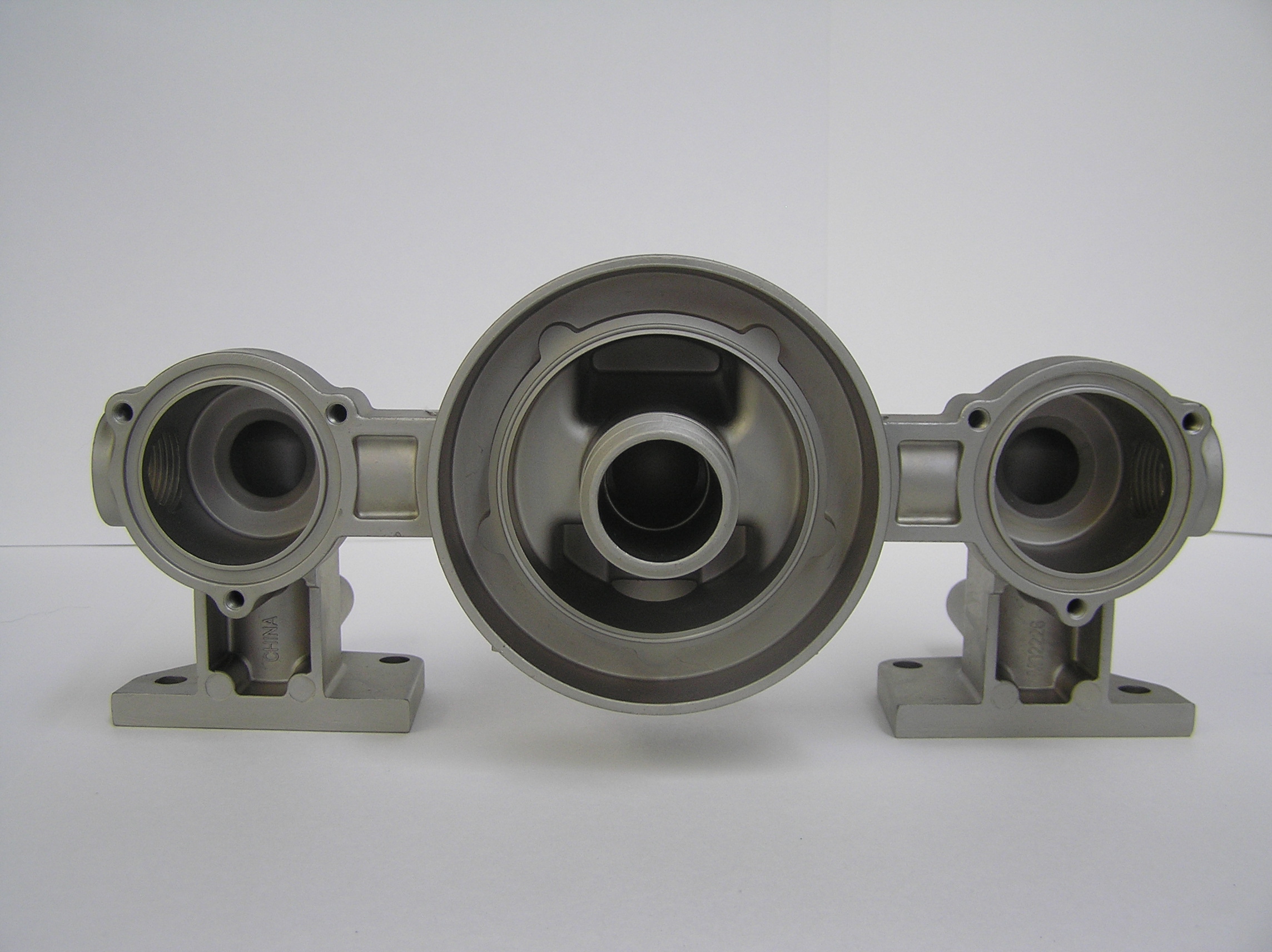

ELECTROLESS NICKEL PLATING

Electroless nickel plating provides good corrosion resistance and hardness (Rc 46-50). Through post-plating heat treatment, hardness values can be increased. The unique quality of electroless nickel plating allows uniform nickel deposition on all exposed substrate surfaces with no build up on edges or coverage voids in recessed areas. This uniform plating thickness can be controlled to +/- 0.00005″. We perform electroless nickel plating on mild steel, brass, stainless steel and aluminum substrates. We plate to meet the requirements of ASTM B733 and AMS 2404 and many other specifications.

ZINC NICKEL PLATING

Zinc nickel plating combines the sacrificial properties of zinc with the barrier to corrosion yielded by nickel. The end result provides salt spray corrosion protection (red rust) exceeding 1000 hours. While zinc nickel plating has found a niche as a replacement for cadmium plating, its use has grown in applications where other coatings fail to deliver sufficient corrosion protection. The appearance has a blue tint, differentiating it from other plated parts.

The deposit is composed of zinc and 5 – 15% nickel. A RoHS compliant post plate passivate is applied, similar to zinc plating. The resulting deposit has a hardness of 250 – 350kg/mm2 Vickers. Zinc nickel plating is also preferable to zinc plating when the finished part comes into contact with aluminum. Applications for zinc nickel plating include automotive, health and safety, aerospace, marine environments, among others. Our process meets the requirements of many specifications including ASTM B841 and AMS 2417, as well as other proprietary specifications.

NICKEL PLATING (BRIGHT)

Electrolytic nickel plating supplies corrosion resistance that is directly proportional to the thickness of plating applied. The attractive appearance and friendly economics of nickel plating make it a sound choice for many applications.

PASSIVATION

The passivation process maximizes corrosion resistance of machined stainless steel parts. This increased corrosion resistance is achieved by removing soils, lubricants, foreign metals, etc. from the part surface. Consequently, the natural tendency for surface oxidation occurs. Properly performed passivation can make the difference between acceptable field performance and premature field failure in stainless steel parts.

ZINC PHOSPHATE (GRAY/BLACK)

Zinc phosphate (gray/black) coating produces an adherent, absorbent layer of zinc on iron and steel surfaces. In this process, a phosphate solution reacts with the surface metal to form a protective layer of insoluble crystalline phosphate. Our application method is immersion. The coating amount is typically measured in weight (milligrams per square foot) rather than coating thickness. We offer a heavy zinc phosphate process that yields a coating weight between 1000 and 3000 milligrams per square foot. The appearance of finished zinc phosphate coating is gray or black. This finish can be used as a prepaint treatment to improve adhesion and to increase corrosion resistance, among other applications. Our zinc phosphate process meets the requirements of TT-C-490, Type I and Mil-P-16232, Type Z.